FINISHING TECHNOLOGY

This is a process of improvement of the wood product quality to give greater prominence to the product by increasing the surface finish characteristics such as shine, colour and protection.

THE SYSTEM

A very suitable system to customise and to emphasise personal products is to adjust the painting process. This involves applying after the first few base coats and/or primer coats a second finishing coat

PURPOSE

The purpose of the finishing coat, in addition to increasing the protection of wood, is to make the surface appearance gloss, matt or, or to give it a satin effect. As a result of this increased requirement, producers that place finishing products on the market have further increased the range of their products, creating fluids that offer many aesthetic effects for the items.

THE PRODUCTS

Finishing products can be of various origins such as wax-, oil-, or synthetic-based. Very often, the viscosity of these products is high and can range from 30 sec Ford4 cup to 500/800s sec ford4 cup, which means, providing a practical example, that these viscosities can be compared to those that of olive oil or even jam.

It is very important that application of the finishing product is carried out as follows:

- with the pieces dismantled so that the protection is 100% on all the surfaces, even those that are not visible when the structure is installed.

- that the surfaces to be treated are clean and free from residue such as dirt, sawdust or other.

- possibly (optional not required) that the surfaces are lightly sanded.

- the finish is applied at a temperature of between 10 and 25 degrees (see also the manufacturer's product specifications)

- the surfaces to be treated are dry (see also the manufacturer's product specifications)

- the quantity of application in grams per square meter is respected (see also the manufacturer's product specifications)

APPLICATION

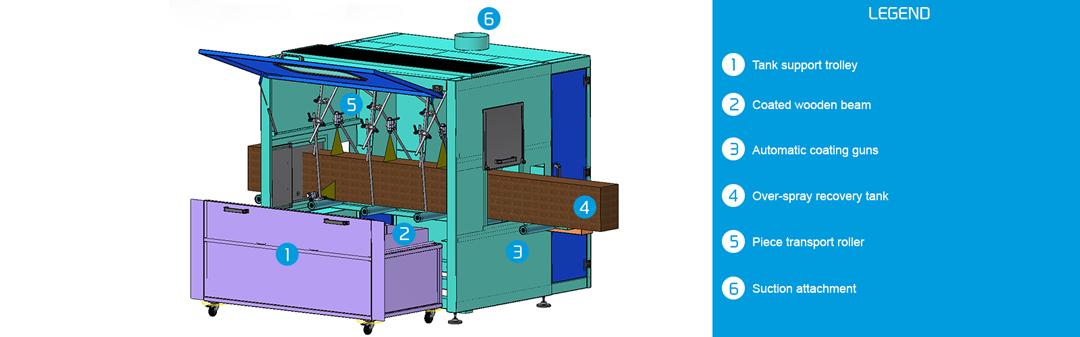

In the treatment lines the finishing varnishes are applied with automatic machines named automatic sprayers and work by coating the piece in a transverse movement. These machines are primarily composed of: a load-bearing structure that doubles as a spray cabin, a series of transport rollers, a series of automatic spraying guns. The functional diagram is shown in the figure below.

EQUIPMENT

Machines of this type can be equipped with different types of spraying systems. The spraying systems includes pump, piping, fittings and guns and are divided into low pressure and high/medium pressure. The choice is made according to the viscosity of the liquid to be sprayed. For low density it is possible to equip the machine with systems that operate at low pressure, for medium or high density it is necessary to adopt systems that operate at medium or high pressure, in principle:

- Low pressure is adopted for the spraying of paints, enamels, primers, oils, in fluid form. Low-pressure spraying equipment normally includes a membrane pump with a compression ratio of 1-1, pneumatic opening automatic guns, pipes, fittings and ordinary components, the working pressure is from 3 to 6 bar.

- Medium/high pressure: It is used for the spraying of products with high density such as lacquers, waxes, gels and oils of high viscosity. high pressure spraying equipment normally involves a gun pump with a compression ratio of 35-150, pneumatic opening automatic guns, piping, fittings and specific high-seal components, the working pressure is between 80-150 bar.

When choosing the type of configuration it is also advisable to obtain information from the suppliers of paints for specific indications.